Why Lean Management?

Lean Management ensures that the human capacities within a company or organisation are used in a smart way in order to create as much value for the customer as possible. A correct application of Lean Management ensures a more efficient organisation with a constant quality and a higher profitability.

But how does working with 5S shadowboards fit in? Lean Management?

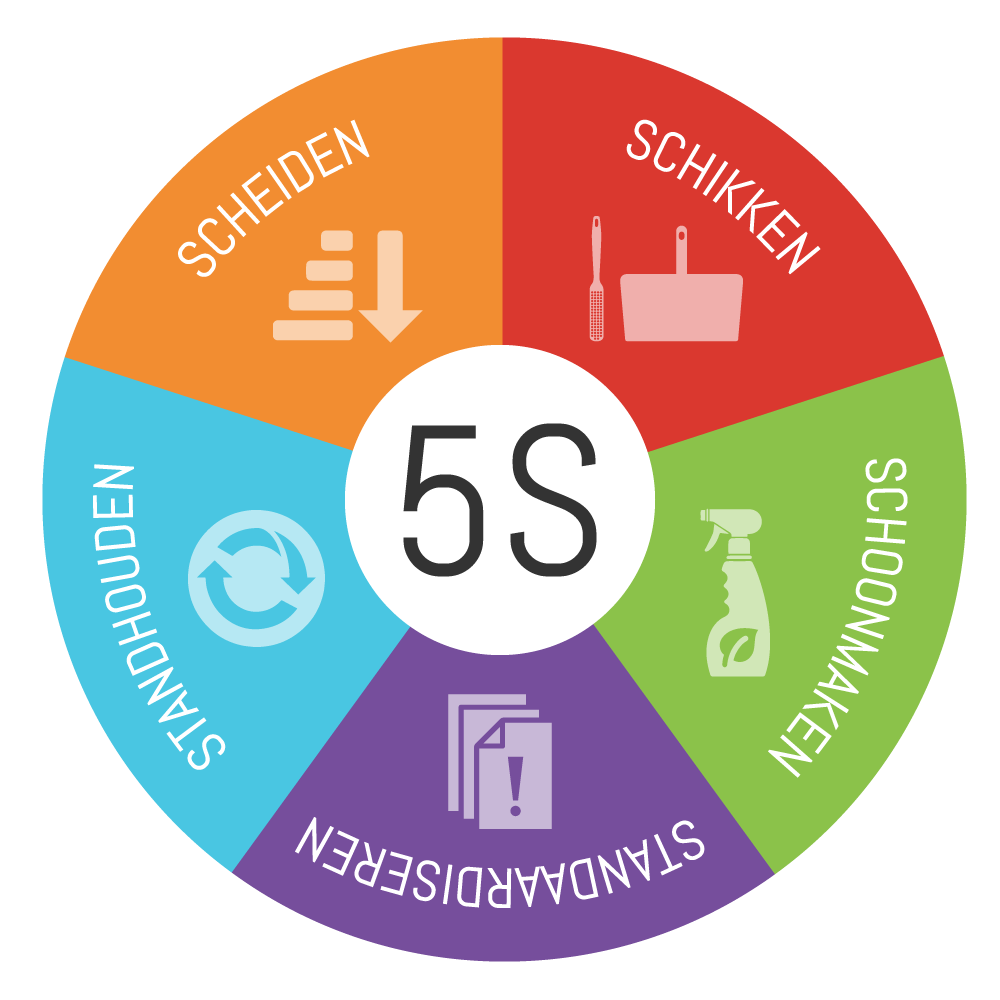

The 5S method is a Lean tool to ensure that the working environment is always neat, tidy and organised. It contributes to better safety, better customer satisfaction, efficiency and employee satisfaction. The 5S method also ensures that there is less wastage, such as wastage of working time, waiting or searching for information, work materials and tools.